Content

RO water treatment is a process that uses a semipermeable membrane to remove ions, molecules, and larger particles from drinking water. This process is known as reverse osmosis (RO) and is commonly used to produce clean and safe drinking water. **Advanta

Update: 22/07/2022

Share:

What is RO Water?

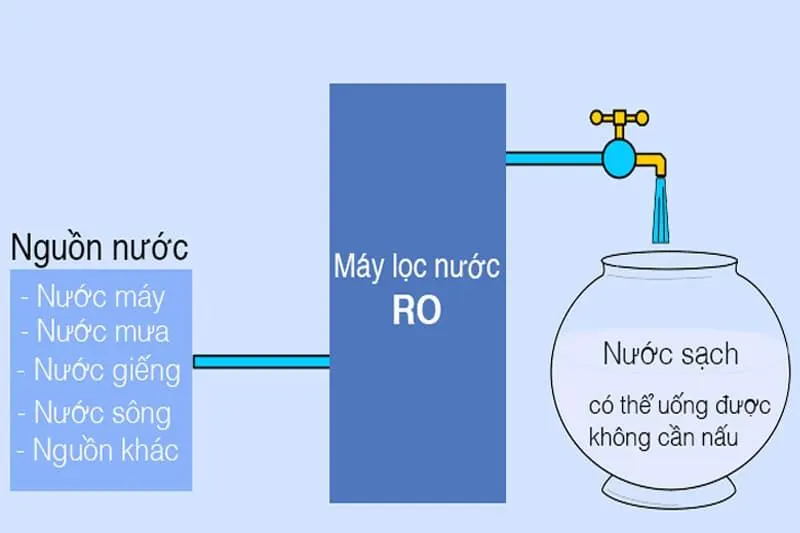

RO water is a type of water created using reverse osmosis technology, abbreviated as RO. This is an advanced technology that combines ultrafine membrane filtration, capable of filtering water at the molecular level with a size as small as 0.0001 micron. With this small size, mainly impurities, metals, viruses, bacteria, etc., can be retained.

The RO water filtration mechanism has a strong flowing water stream that creates high pressure to transfer substances to low-pressure areas and continue to be transported to the next part for filtration, resulting in purified water up to 99%.

What is the RO Water Treatment Technology?

The RO water treatment technology is abbreviated by the term: Reverse Osmosis. This type of technology is mainly applied in the maritime and aerospace industries in the United States.

With this technology, water will be processed with an efficiency of recovering clean water up to 40% - 60% and only about 25% of water is discharged. Through modern treatment technology, your water source will be purified with all the necessary minerals for health.

Principle of Operation of RO Water Treatment Technology

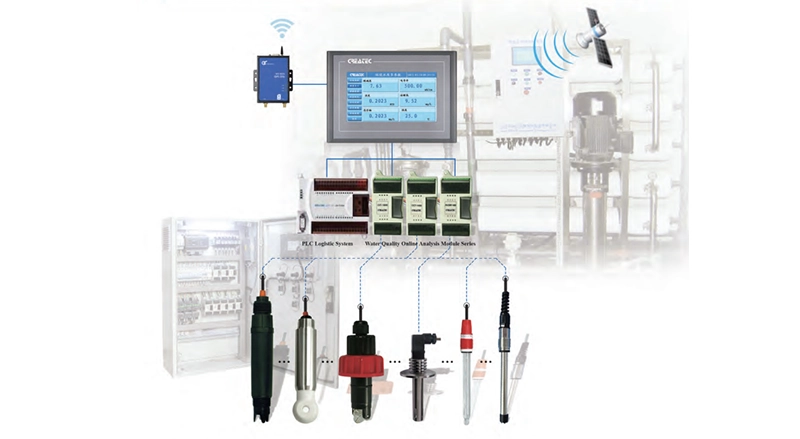

The operating principle of this technology goes through the following steps:

- Step 1: Untreated water will be transported to tank B1. Here, the whole house coarse filtration device and ACF odor remover will eliminate unpleasant odors, impurities, and dirt particles in the water.

- Step 2: Odor-removed water is then passed through a softening device to remove Ca2+, Mg2+ ions, etc.

- Step 3: The water is then directed to the fine filter. In this area, water will be rid of impurities with extremely small sizes of only > 10 microns. After completion, the water will be transferred to the water tank.

- Step 4: In the water tank, there are 2 pumps used to support the vertical high-pressure pump, the high-pressure pump continues to pump water into the RO reverse osmosis device. With water entering the reverse osmosis device, impurities are removed, and essential minerals in natural water are retained.

- Step 5: The water will then pass through a 0.2-micron fine filter with a sterilization device using UV light. After passing through this component, the water can be consumed directly without boiling.

- Step 6: Finally, the water will be transferred to the finished product tank. In this tank, there are 2 circulating pumps that operate alternately to transport water to the point of use. This is the final stage in the RO water treatment process.

Advantages and Disadvantages of RO Water Treatment Technology

Advantages

Some advantages of this technology that you can see include:

- This is the most advanced water filtration technology today. With RO membranes, it can filter and remove all types of bacteria, impurities with extremely small sizes of 0.0001 micron. It provides you with the purest, sweetest water source.

- Water after the filtration process can be consumed directly, which is very good for health.

- It can be used with various water sources: well water, tap water, etc. Due to this characteristic, RO water treatment technology is highly favored in the market today.

Disadvantages

However, this technology still has some disadvantages such as:

- Some natural minerals in water such as Mg, Calcium, etc., can also be removed.

- Since this technology requires high pressure to push water into the filter membrane, it will consume a lot of electricity. Therefore, power surges or high power consumption are common occurrences.

- There will be wastewater discharged after the filtration process.

Applications of RO Water Treatment Technology

Bottled Water Production

This technology is applied in the following process:

- The incoming water source is passed through a filter column to remove undesirable impurities such as iron, lead, manganese, etc., before being stored in the source water tank.

- Next, the water is pumped from the source water tank to the filtration system to start the filtration process.

- The water will pass through the initial filter device to remove large-sized sediments of about 5 microns.

- It will then be transferred to a multi-substance removal device to process easily soluble compounds in water.

- After basic purification, the water will pass through a water softening device. This process will reduce the concentration of calcium, magnesium ions, making the water taste good, sweet, and naturally pure.

- Subsequently, the water will be transferred to the tank preparing water supply for the RO water treatment system to operate.

- The water flowing through the RO membrane is pumped at extremely high pressure. The RO membrane filters and removes ultra-small particles of about 1 micrometer.

Food Processing Technology

The food processing industry requires extremely high hygiene standards as it directly affects consumer health. Therefore, in any process, it is necessary to ensure food safety and hygiene requirements.

The RO filtration system has been applied to the processing of food products with high-quality water requirements or traditional fermented products, such as producing soft drinks, food processing plants, beer and wine production, etc.

The input water with a conductivity of 300 - 800 μS/cm, after passing through the industrial RO water filtration system, the conductivity will decrease to only 4 - 12 μS/cm. This index is suitable for all requirements in the food processing industry.

Application of RO Water Filtration System in the Medical Industry

In the medical industry, purified water is used for preparing oral medications, pharmaceuticals, medical instrument cleaning, wound irrigation. All of these applications require water that meets purity requirements to protect the health of patients.

In addition, purified water is also used for artificial kidney dialysis for patients with kidney failure. Therefore, if the water used is not guaranteed, it will have serious consequences for patients.

Considerations When Using RO Water Treatment Technology

This technology provides you with pure water, but only when all its components meet quality standards. Therefore, when purchasing this product line, you need to pay attention to its origin to avoid buying counterfeit or fake products.

Here are some considerations to help you choose the right product line:

- Choose a machine with a clear origin to ensure that the technology meets standards.

- Select a machine with all the necessary parts according to the standard of RO water treatment technology. It should also come with a warranty.

- Have a certificate, proof of origin, and product quality inspection.

- Choose a reputable, long-standing supplier.

With this basic information, you must have everything you need before making a decision to choose this technology, right? Hopefully, with this reference information, you will choose the best product with RO water treatment technology. Contact Toan A via hotline 0913.543.469 for advice today!

Update: 22/07/2022

Share:

Related news

Industrial RO water filtration system: Optimal solution for clean water in production

Created at: 17/09/2024

Water purification is an essential process in many industries, especially in the pharmaceutical, electronics, and power generation sectors. One of the most effective methods for producing ultra-pure water is the DI-EDI water purification system. This syst

With the rapid development of modern industries today, pure water has played an extremely important role, not only as a crucial raw material for production but also as a decisive factor affecting product quality. Particularly in industries such as pharmaceuticals, electronics, energy, and food, the water source is required to be ultrapure. The DI (Deionization) water filtration system and EDI (Electrodeionization) have become the two leading technologies to meet this demand. Each system has its own advantages and limitations, suitable for specific industrial applications. Let’s explore the details of DI and EDI water filtration technologies with Toan A JSC in the article below!

Created at: 19/08/2024

Details of the structure, pricing of industrial RO water filtration system.

Clean water is not only an essential component but also a determining factor in the product quality of industrial enterprises operating in various industrial sectors today. Especially for industries such as food, pharmaceuticals, and electronics, ensuring clean water sources is a prerequisite for maintaining safety and hygiene standards. However, the issue of clean water in industrial production is currently facing many challenges, including increasing water pollution and pressure from unsustainable industrial development. Therefore, the application of advanced water filtration technologies, with the most common being industrial RO water filtration systems, has become the optimal solution chosen by many businesses to invest in. What are the capacities of these systems and how do they fit the production scale of businesses? Let's explore the details with TOÀN Á JSC in the following article!

Created at: 14/08/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News