Content

Pharmaceuticals and Cosmetics Solution

Update: 04/01/2025

Share:

An efficient cosmetics wastewater treatment system helps ensure that the treated water meets the wastewater standards set by the Vietnamese Ministry of Health. This is crucial in the context of factories and enterprises treating their wastewater.

Cosmetics Wastewater Treatment

Cosmetics wastewater treatment usually involves removing pollutants such as chemicals and organic compounds from the wastewater before it is discharged into the environment. This process may include multiple stages such as pretreatment, biological treatment, and chemical treatment to ensure that the wastewater meets safety standards.

.jpg)

Benefits of Cosmetics Wastewater Treatment

Treating cosmetics wastewater brings many important benefits, including:

- Environmental protection: Minimizing water and soil pollution, protecting the natural ecosystem.

- Community health: Preventing the spread of harmful substances and their impact on human health.

- Compliance with legal regulations: Ensuring that businesses comply with environmental protection regulations.

- Cost savings: Reducing wastewater treatment costs and avoiding penalties from regulatory agencies.

- Business image: Enhancing the reputation and social responsibility of the business in the eyes of the community and customers.

Methods of Cosmetics Wastewater Treatment

For cosmetics wastewater treatment, there are specific methods available:

Physical Methods

Physical methods, also known as mechanical methods, involve using structures, machinery, or equipment to remove large-sized waste materials from water.

.jpg)

Collecting and separating impurities and suspended solids from the water source will help the subsequent water treatment processes operate more smoothly and reliably. This helps prevent blockages or damage to wastewater pipes and other treatment equipment.

Chemical Methods

Chemical reactions help reduce the level of pollution in water. Notable examples include using ozone and chlorine to oxidize organic compounds into inorganic compounds after biological treatment.

Biological Methods

For this method, microorganisms are used to treat polluted wastewater. These microorganisms decompose high levels of organic compounds present in cosmetics wastewater.

This method is mainly divided into 3 types:

- Aerobic biological treatment.

- Anaerobic biological treatment.

- Anoxic biological treatment.

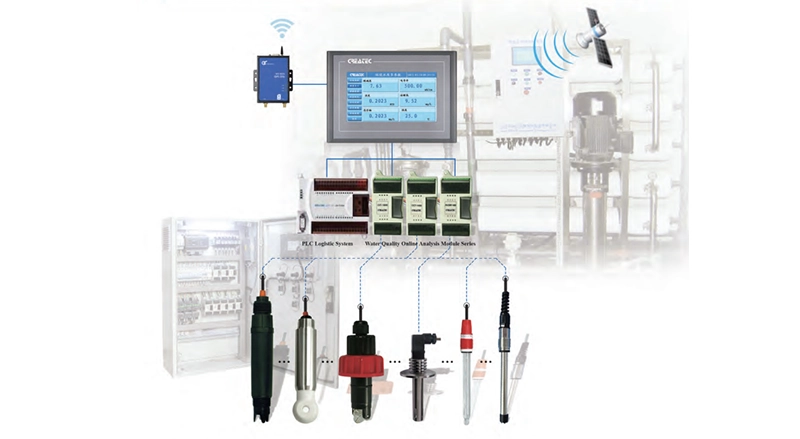

Current Technology for Cosmetics Wastewater Treatment

.jpg)

Cosmetics Industry Wastewater Treatment System

The cosmetics industry wastewater treatment system includes specific stages as follows:

Trash Rack

Cosmetics wastewater passes through a trash rack to filter and retain large-sized impurities. This process prevents blockages in the pipeline system and subsequent treatment facilities. The collected trash is then gathered and treated using specialized methods.

Equalization Tank

The basic function of the equalization tank is to stabilize the concentration and flow rate of pollutants. The tank uses aeration devices to prevent sedimentation or anaerobic decay at the tank bottom.

Flotation Tank

In the flotation tank, some of the surfactants and suspended solids are removed to make the water cleaner.

Flocculation Tank

In this tank, flocculants and coagulants are added to bond the flocculant particles in the water into large flocs. This makes it easier to separate them from the water source.

Settling Tank 1

The previous flocculation process allows settling to occur more effectively in Tank 1. The settled sludge is then transferred to a sludge storage tank. The floating wastewater is transferred to the anaerobic biological treatment tank (UASB).

UASB Tank

Here, the biological treatment of cosmetics wastewater using anaerobic biological activity takes place with anaerobic microorganisms. This process helps reduce the organic pollutants significantly. Additionally, the UASB tank also helps remove N and P.

Aerotank

Also known as the aerobic biological tank. In the UASB tank, some organic compounds may not have been fully treated, so the wastewater is further sent to the Aerotank for continued decomposition using aerobic microorganisms.

.jpg)

Continuous oxygen supply is essential for the aerobic microorganisms to function properly in the tank.

Settling Tank 2

Here, biological sludge settling occurs. A portion of the settled sludge is returned to the Aerotank, while another portion is sent to a specialized sludge storage tank for further treatment. The clarified water from settling tank 2 meets the required standards and can be discharged to the receiving water body.

By using these treatment systems and methods, meeting the standard for cosmetics wastewater treatment significantly contributes to protecting the natural ecological environment, improving the quality of life for humans, and meeting stringent standards from the Ministry of Natural Resources and Environment. This helps avoid the risk of penalties and enhances the reputation of the business.

Currently, Toan A provides cosmetics industry wastewater treatment systems for many businesses in this sector. With years of experience and a highly qualified technical team, Toan A is committed to providing the best water treatment solutions available.

Update: 04/01/2025

Share:

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News