Content

Details of the structure, pricing of industrial RO water filtration system.

Update: 14/08/2024

Share:

I. What Are the Advantages of Industrial RO Water Filtration System?

Reverse Osmosis (RO) water filtration technology is one of the most advanced and effective technologies today, especially when applied in the industrial sector, with the following outstanding advantages:

1. High Contaminant Removal Capability

RO technology can remove up to 99% of impurities, bacteria, viruses, and heavy metal ions in water, ensuring that the filtered water meets safety standards.

2. Cost-Effective

Compared to traditional water filtration methods, RO technology consumes less electricity and has low maintenance costs, helping businesses save on operational expenses.

3. Wide Application Range

RO water filtration systems can be customized to meet the specific needs of various industries, from food production to chemical processing.

4. Environmentally Friendly

The RO filtration process does not use chemicals, therefore it does not cause environmental pollution, aligning with the current trend of sustainable development.

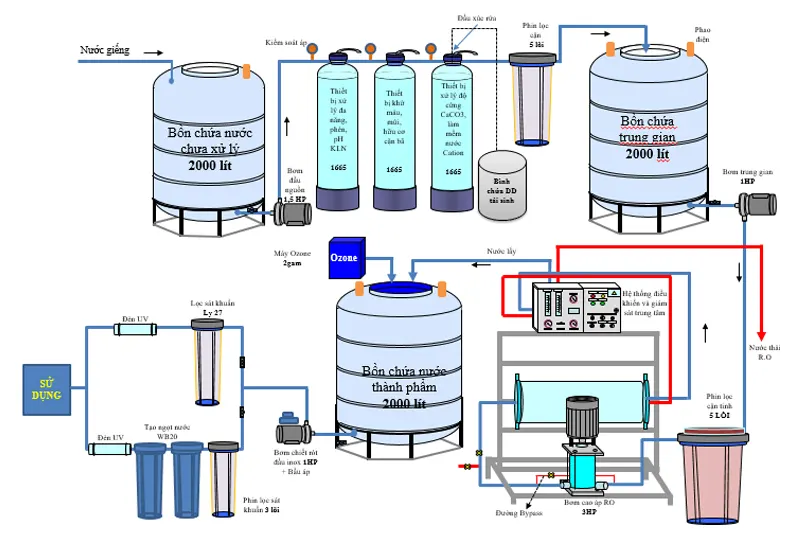

II. Structure of Industrial RO Water Filtration System

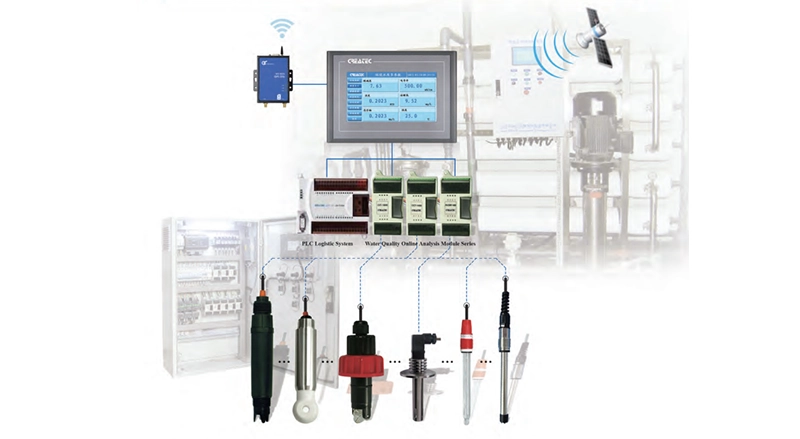

The industrial RO water filtration system consists of several main components, each playing a specific role in the water treatment process, including:

1. Raw Water Storage Tank

The raw water storage tank is responsible for storing raw water from the supply source, usually made of stainless steel or high-strength plastic due to their corrosion resistance and high durability, ensuring no impact from environmental and chemical factors in the water.

2. Pre-Treatment Filtration System

Includes sand filtration, activated carbon filtration, and water softening. Specifically:

Sand Filtration

The filter housing is usually made of high-strength plastic or stainless steel, with quartz sand as the filter media. The sand filter functions to remove large sediment particles and mechanical impurities from raw water, protecting subsequent filtration components. Quartz sand effectively filters out dust particles and large impurities, making the water cleaner before proceeding to the next treatment steps.

Activated Carbon Filtration

The filter housing is also made of plastic or stainless steel, containing activated carbon inside. The function of this filter is to remove odors, colors, and dissolved organic compounds in water. Activated carbon has the ability to absorb organic compounds and chemicals, improving water quality in terms of sensory and chemical aspects.

Water Softening

The filter housing is usually made of high-strength plastic or stainless steel, containing ion-exchange resin beads (water softening material), which functions to reduce the hardness of water, prevent scaling on RO membranes and other equipment. Water softening material helps remove calcium and magnesium ions, making the water less prone to dirt buildup.

3. High-Pressure Pump

This is a necessary device to push water through the RO membrane. The pump casing is usually made of aluminum alloy or stainless steel, with internal parts made of ceramic or other corrosion-resistant materials. The high-pressure pump provides the necessary pressure to push water through the RO membrane, ensuring that the water is pushed with enough pressure for water molecules to permeate through the membrane, while maintaining the system's efficiency and lifespan.

4. RO Membrane

As the main component of the system, RO membranes are usually made of polyamide or cellulose acetate, wrapped in a plastic or stainless steel casing. RO membranes have the ability to remove impurities, bacteria, viruses, and dissolved mineral ions in water. The pore size of RO membranes is very small, allowing only water molecules to pass through the membrane, retaining pollutants.

5. Treated Water Storage Tank

Similar to the raw water storage tank, the treated water storage tank is usually made of stainless steel or high-strength plastic. The water after passing through the RO membrane will be stored in this tank before being used or continuing through the next treatment stages, ensuring that the water is always ready and meets the required standards when needed.

6. Post-RO Water Filtration System

This system includes polishing filtration, UV disinfection, and Ozone treatment. Specifically:

Polishing Filtration

The filter housing is made of high-strength plastic or stainless steel, containing polishing filter fibers or membranes to remove remaining ultrafine particles after passing through the RO membrane, ensuring the highest water purity.

UV Disinfection

UV disinfection equipment usually has a stainless steel or high-quality plastic casing, with UV lamps inside to kill bacteria, viruses, and remaining disease-causing agents in water using ultraviolet rays. UV technology is an effective method to ensure completely clean water.

Ozone Treatment

Ozone disinfection equipment is usually made of high-strength plastic or stainless steel, with ozone generation components, used to disinfect and remove remaining odors in water. Ozone has high oxidation ability, helping to remove organic compounds and bacteria, ensuring clean and safe water.

III. Detailed Quotation for Large-Capacity Industrial RO Water Filtration System

The cost of a large-capacity industrial RO water filtration system depends on various factors, including capacity, materials, brand, and specific technical requirements. Below is some reference pricing information based on machine capacity:

| No. | Product | Price (VND) |

| 1 | Industrial water filter 200l/h | 35,000,000 |

| 2 | 300l/h capacity water filter machine | 48,000,000 |

| 3 | Industrial water filter 500l/h | 52,000,000 |

| 4 | Industrial water filter 750l/h | 90,000,000 |

| 5 | Large capacity water filter machine 1000l/h | 110,000,000 |

| 6 | Industrial RO water filter 1200l/h | 140,000,000 |

| 7 | Industrial drinking water filtration system 1500l/h | 180,000,000 |

| 8 | Large capacity RO water filter machine 2000l/h | Contact |

| 9 | Industrial RO Water Filtration System 3000l/h | Contact |

Note: The above costs do not include installation, operation, and maintenance costs. For more details, customers with needs please contact the hotline: 0913.543.469

IV. Considerations When Choosing to Install an Industrial RO Water Filtration System

In addition to costs, businesses in need of installing an industrial RO water filtration system should also consider the following issues:

- Identify specific needs: Before choosing to install a water filtration system, businesses need to clearly define the need for clean water and the required capacity of their business to allow the consulting unit to provide the most suitable solution.

- Choose a reputable brand: Choosing products from reputable brands will ensure the quality and durability of the system.

- Check the quality of the raw water: Evaluate the quality of the raw water to determine the configuration and suitable filters.

- Regular maintenance: Perform regular maintenance to ensure the system operates efficiently and prolong its lifespan.

- Find a professional installation partner: Choose an experienced and professional installation unit to ensure the system is deployed accurately and effectively.

V. Toàn Á JSC - Leading Consultation and Installation Unit for High-Quality Industrial RO Water Filtration Systems

With over 21 years of experience and more than 4000 projects, large and small, completed nationwide, Toàn Á JSC has established itself as one of the leading units in providing and installing industrial RO water filtration systems. We pride ourselves on having a team of professional technicians, committed to providing optimal water filtration solutions that meet all customer needs.

- Genuine products: We commit to providing genuine imported products, ensuring superior quality and durability.

- Professional consultation: Toàn Á JSC's experienced experts and technical advisory team are always ready to support customers in choosing the most suitable industrial RO water filtration system according to their needs and budget.

- Comprehensive services: Toàn Á JSC provides fast installation services, regular maintenance, and 24/7 technical support, ensuring the system operates efficiently and durably.

- Competitive costs: We commit to providing products and services at reasonable, competitive prices in the market, helping customers optimize their investment costs.

The industrial RO water filtration system is an ideal solution for clean water needs in production and daily life. Choosing the right system not only helps businesses save costs but also improves production efficiency and ensures the quality of the output products. Contact Toàn Á JSC for detailed consultation and installation of high-quality industrial RO water filtration systems that meet all business requirements. Toàn Á JSC is always ready to accompany you on the path of sustainable and safe development.

- Zalo: 0913.543.469

- Projects: 0913.543.469

- North Hotline: 0822.211.666

- South Hotline: 0822.212.666

- Messenger: https://www.facebook.com/toanajsc

Update: 14/08/2024

Share:

Related news

Industrial RO water filtration system: Optimal solution for clean water in production

Created at: 17/09/2024

Water purification is an essential process in many industries, especially in the pharmaceutical, electronics, and power generation sectors. One of the most effective methods for producing ultra-pure water is the DI-EDI water purification system. This syst

With the rapid development of modern industries today, pure water has played an extremely important role, not only as a crucial raw material for production but also as a decisive factor affecting product quality. Particularly in industries such as pharmaceuticals, electronics, energy, and food, the water source is required to be ultrapure. The DI (Deionization) water filtration system and EDI (Electrodeionization) have become the two leading technologies to meet this demand. Each system has its own advantages and limitations, suitable for specific industrial applications. Let’s explore the details of DI and EDI water filtration technologies with Toan A JSC in the article below!

Created at: 19/08/2024

Details of the structure, pricing of industrial RO water filtration system.

Clean water is not only an essential component but also a determining factor in the product quality of industrial enterprises operating in various industrial sectors today. Especially for industries such as food, pharmaceuticals, and electronics, ensuring clean water sources is a prerequisite for maintaining safety and hygiene standards. However, the issue of clean water in industrial production is currently facing many challenges, including increasing water pollution and pressure from unsustainable industrial development. Therefore, the application of advanced water filtration technologies, with the most common being industrial RO water filtration systems, has become the optimal solution chosen by many businesses to invest in. What are the capacities of these systems and how do they fit the production scale of businesses? Let's explore the details with TOÀN Á JSC in the following article!

Created at: 14/08/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News