Content

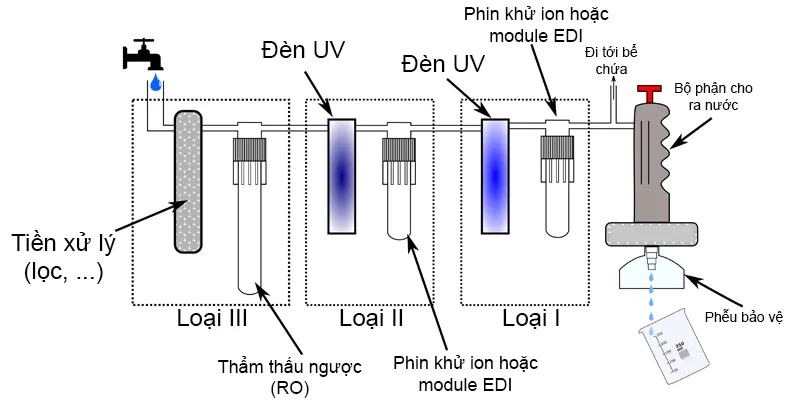

Water purification is an essential process in many industries, especially in the pharmaceutical, electronics, and power generation sectors. One of the most effective methods for producing ultra-pure water is the DI-EDI water purification system. This syst

Update: 19/08/2024

Share:

I. Outstanding Features of DI Water Filtration System

The DI (Deionization) water filtration system is one of the advanced technologies used to remove dissolved ions in water, aiming to achieve high purity for applications that require the best water quality. The DI process involves ion exchange, where positive (cation) and negative (anion) ions in water are replaced by hydrogen (H+) and hydroxyl (OH-) ions. The result of this process is ultra-pure water, free from ion impurities that can hinder industrial production processes.

Compared to other water filtration technologies, water treatment systems using DI technology have the following outstanding features:

1. High Filtration Efficiency

DI water treatment technology has the ability to remove almost all dissolved ions, helping water achieve the highest purity level. This is particularly important in industrial sectors that require high water quality such as pharmaceuticals and semiconductor manufacturing.

2. Easy Operation and Maintenance

DI water filtration systems are designed to be easy to operate and maintain. The process of replacing and regenerating ion exchange resins is simple, does not require complex technical skills, and helps save time and costs for businesses.

3. Flexibility in Design

DI water treatment systems can be customized to meet the specific needs of different industries. From small systems for laboratories to large systems for industrial plants, DI can meet various requirements effectively.

4. Integration with Other Filtration Technologies

DI can easily be integrated with other water filtration systems such as reverse osmosis (RO) to enhance filtration efficiency and ensure the best quality of the output water.

5. Wide Applications in Many Modern Industries

DI water treatment systems are commonly installed and applied in industrial sectors that require ultra-pure water quality. Specifically:

- Pharmaceutical and Medical Industry: DI water filtration systems provide ultra-pure water, meeting the stringent standards of this industry, from drug manufacturing to healthcare products.

- Electronics Industry: Manufacturing microchips and electronic components requires an environment free from impurities to ensure product accuracy and performance. DI water treatment systems are widely used for cleaning and surface treatment in these manufacturing processes.

- Energy Sector: In the energy sector, especially in power generation, DI water treatment systems are used to supply water to boilers and other equipment to minimize corrosion and scale buildup, thereby improving equipment efficiency and lifespan.

- Food and Beverage Industry: DI water filtration technology is used in food and beverage production to ensure food safety and maintain the natural flavor of products.

II. Key Features of EDI Water Filtration System

The EDI (Electrodeionization) water filtration system is an advanced technology that combines ion exchange and electro-permeation processes to produce ultra-pure water. This is a significant development in the field of water treatment, allowing the removal of dissolved ions without the need for chemical regeneration as in traditional ion exchange systems. EDI operates by using electric current to move and remove ions through ion exchange membranes, providing superior water filtration efficiency and environmental friendliness.

Compared to other water filtration technologies, the EDI water filtration system has several outstanding advantages:

1. High Filtration Efficiency

EDI systems can remove most ion impurities, achieving very low electrical conductivity, usually below 0.1 µS/cm, meeting the strict purity requirements in many industries.

2. Environmentally Friendly

One of the biggest advantages of EDI is the absence of chemical regeneration, minimizing negative impacts on the environment and reducing costs for chemical waste treatment.

3. Continuous and Stable Operation

EDI is designed to operate continuously without the need for regeneration breaks like traditional ion exchange systems, helping save time and improve production efficiency.

4. Cost-Effective Operation

Due to the absence of chemical usage and the ability for continuous operation, EDI systems help reduce operation and maintenance costs compared to other water filtration technologies.

5. Applications of EDI Water Treatment Technology

EDI water filtration systems are the optimal solution for industries that require ultra-pure water, thanks to their superior filtration capabilities.

- Pharmaceutical and Medical Industry: EDI water filtration systems provide the necessary ultra-pure water for pharmaceutical production and healthcare products, meeting GMP standards and strict water quality requirements.

- Electronics and Semiconductor Industry: Ultra-pure water is a critical factor in the production of electronic components and microchips, where any impurities can cause serious manufacturing defects. EDI is an ideal choice to ensure the highest purity level for water used in this industry.

- Energy Sector: In power plants, EDI water is used to supply water to boilers and cooling systems, helping prevent corrosion and extend the lifespan of equipment.

- Food and Beverage Industry: EDI water filtration technology ensures high-purity water, free from harmful impurities, making it a perfect choice for food and beverage production to maintain natural flavors and product quality.

III. Comparison of DI and EDI Water Filtration Technologies

DI and EDI are the most advanced water filtration technologies today, providing ultra-pure water for various industrial applications. However, these two technologies also have certain differences.

1. Similarities

DI and EDI water filtration systems both use ion exchange technology to remove ion impurities in water to produce high-purity water for industrial sectors that require strict water quality standards such as pharmaceuticals, electronics, energy, and food.

2. Differences

In terms of operation mechanism:

- DI: Relies on traditional ion exchange processes, where cation and anion resins need periodic regeneration to maintain ion removal capabilities.

- EDI: Combines ion exchange and electro-permeation processes, allowing continuous ion removal without the need for regeneration breaks.

In terms of water filtration efficiency:

- DI: Effective in removing ions but depends on the quality of ion exchange resins and regeneration processes.

- EDI: Provides absolute efficiency, producing water of very high purity, often referred to as ultra-pure water.

Real-world applications:

- DI: Suitable for manufacturing businesses in industries that do not require extremely stringent water purity or have budget constraints.

- EDI: Ideal for industries that demand absolute water purity such as semiconductor manufacturing, pharmaceuticals, and energy production, where stopping production for resin regeneration can be costly.

IV. Choosing the Right DI and EDI Water Filtration System Installation with Dedicated Consultation from Toan A JSC

With 21 years of experience in the water treatment industry, Toan A JSC is proud to be a consulting and installation provider of DI and EDI water treatment systems for a wide range of investors, including:

- DI water treatment system with a capacity of 300 m3/day for Vinfast Automobile Company.

- DI water treatment system with a capacity of 1,200 m3/day for applications in Electronics and Medical industries for Ecotech Company at Pho Noi Industrial Zone, Hung Yen.

- DI water treatment system for industrial Aluminum production, with a capacity of 500 m3/day at Pho Noi Industrial Zone, Hung Yen.

- RO and DI water treatment system for SEOJIN AUTO, with a capacity of 400 m3/day at Song Khe Industrial Zone, Bac Giang.

- Pharmaceutical-grade EDI water treatment system, EU standard, with a capacity of 2000L/H for Hai Duong Medical Equipment Pharmaceutical Joint Stock Company.

- RO 2-stage - Ultra-pure EDI water treatment system for pharmaceutical and cosmetic production, with a capacity of 1000L/h for Vimac Cosmetics Joint Stock Company at Nguyen Khe Industrial Zone, Dong Anh, Hanoi.

And over 4000 other water treatment projects nationwide.

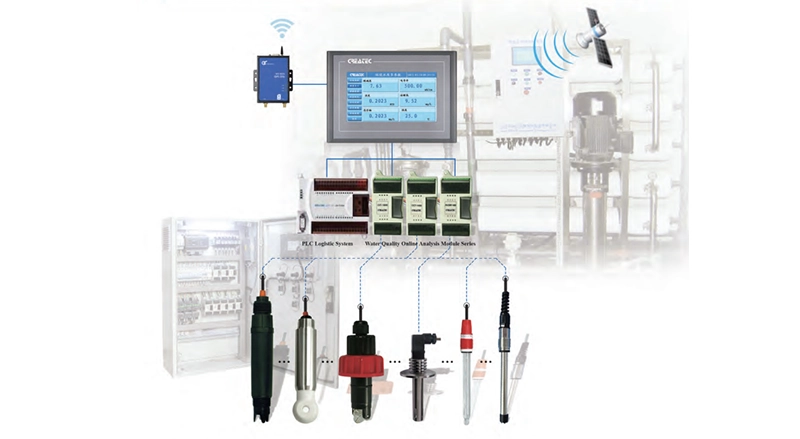

Toan A JSC confidently asserts itself as a leading unit, providing detailed consulting services to help customers assess their ultra-pure water needs, compare the costs and benefits of DI and EDI systems to make the optimal choice.

With a team of highly skilled and experienced technicians, Toan A JSC ensures that the construction and installation process is fast and efficient while committing to comprehensive technical support to ensure stable and durable system operation.

We also offer competitive pricing for both DI and EDI systems, tailored to each business's budget. For quality DI and EDI water filtration system consulting and installation, customers can contact Toan A JSC to receive the best support from our team of experts.

- Zalo: 0913.543.469

- Projects: 0913.543.469

- Hotline North: 0822.211.666

- Hotline South: 0822.212.666

- Messenger: https://www.facebook.com/toanajsc

Update: 19/08/2024

Share:

Related news

Industrial RO water filtration system: Optimal solution for clean water in production

Created at: 17/09/2024

Water purification is an essential process in many industries, especially in the pharmaceutical, electronics, and power generation sectors. One of the most effective methods for producing ultra-pure water is the DI-EDI water purification system. This syst

With the rapid development of modern industries today, pure water has played an extremely important role, not only as a crucial raw material for production but also as a decisive factor affecting product quality. Particularly in industries such as pharmaceuticals, electronics, energy, and food, the water source is required to be ultrapure. The DI (Deionization) water filtration system and EDI (Electrodeionization) have become the two leading technologies to meet this demand. Each system has its own advantages and limitations, suitable for specific industrial applications. Let’s explore the details of DI and EDI water filtration technologies with Toan A JSC in the article below!

Created at: 19/08/2024

Details of the structure, pricing of industrial RO water filtration system.

Clean water is not only an essential component but also a determining factor in the product quality of industrial enterprises operating in various industrial sectors today. Especially for industries such as food, pharmaceuticals, and electronics, ensuring clean water sources is a prerequisite for maintaining safety and hygiene standards. However, the issue of clean water in industrial production is currently facing many challenges, including increasing water pollution and pressure from unsustainable industrial development. Therefore, the application of advanced water filtration technologies, with the most common being industrial RO water filtration systems, has become the optimal solution chosen by many businesses to invest in. What are the capacities of these systems and how do they fit the production scale of businesses? Let's explore the details with TOÀN Á JSC in the following article!

Created at: 14/08/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News