Content

Bottled and Packaged Drinking Water Solution

Update: 05/07/2022

Share:

The process of producing bottled water includes three main stages: purifying drinking water, bottling, and capping the finished bottles.

The process of producing purified bottled water includes three main stages: purifying drinking water, bottling, and capping the finished bottles. If you want to learn more, follow this article!

What is Bottled Water?

Bottled water is a type of water that is clear in color, containing minerals and natural CO2. It can also be water that is supplemented during the production process, taken from natural sources. It is not mineral water, does not contain sugar or any sweetening agents, flavorings, or other food additives.

.jpg)

Bottled drinking water is a term used to refer to various types of water bottled in containers. It includes the composition of two main components: water and the bottle, as follows:

Currently, purified water is widely used in Vietnam as well as in other countries around the world. However, contrary to that, very few people know, understand accurately, and fully about them. Water composition: The water used for bottling is completely different from other types of sweetened water, carbonated water, flavored water, or any other food components.

Benefits of Bottled Water Production

Up to the present time, in Vietnam as well as in countries around the world, there are many different bottled water production facilities. Each facility has its own process of purifying and bottling water, providing different quality, promoting the development of unique brands.

.jpg)

The reason why this type of water is increasingly popular and widely used in Vietnam and many other countries around the world is because of the tremendous benefits it brings:

- Ensures cleanliness, safety for health.

- Compact, very convenient to use, easy.

- Beautiful bottle design, providing a comfortable feeling for users.

- Protects the health of every citizen by using clean purified water that meets safety standards.

- Provides good jobs and income for many people.

- Solves employment issues, contributes to reducing social problems, and improves the quality of life.

The market for bottled purified water is very vibrant, developing strongly, promising to grow even more in the future with an increasing number of users and a growing number of production facilities.

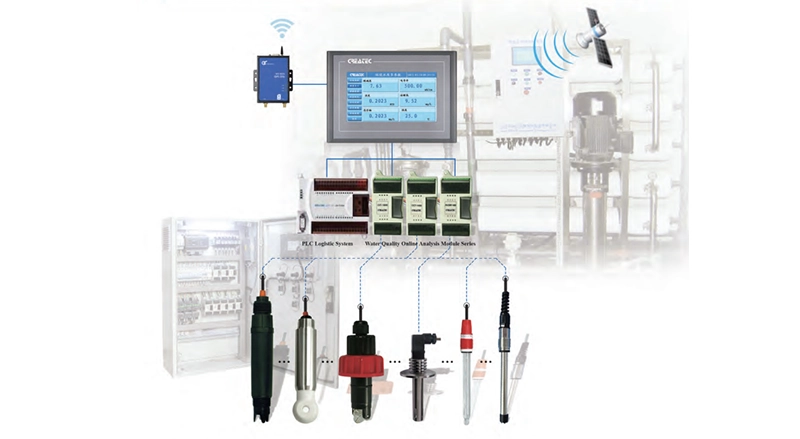

Standard Process for Producing Safe and Clean Bottled Water

The entire production line of bottled water that is clean and safe includes the proper and delicate combination of: clean production, bottling, and capping.

.jpg)

It is divided into steps as follows:

Step 1: Selecting the Water Source

Groundwater is mainly used in the purified water production line. Because it is abundant, of stable quality, convenient, easy to handle, and cheaper than other water sources.

Step 2: Coarse Filtration

When the water source is turbid, contains sediment or suspended particles, it is necessary to carry out coarse filtration using a source head filter. The source head filters will be adjusted to suit the characteristics and properties of the water source. They can effectively remove sediments, suspended particles, odors, heavy metals (such as iron, manganese...), phenols... After the water is roughly filtered, it will be directed to an intermediate storage tank.

Step 3: Removing Harmful Substances and Bacteria

The RO permeable membrane filtration system consists of the main filtration system and the auxiliary filtration system, capable of completely filtering out all harmful substances and bacteria. After the water is rid of harmful substances and bacteria, it will be directed to the finished product tank.

Step 4: Disinfection and Prevention of Bacterial Recontamination

Using an ozone generator to completely kill bacteria, sterilize the water. Then the water passes through a fine sediment filter and uses UV light to kill bacteria. At the end of this step, the water is clean, clear, resistant to bacterial recontamination, and has a natural sweet taste.

Bottling and Capping Process

.jpg)

This process is divided into steps as follows:

- Step 1: All sterilized bottles are automatically transferred to the water filling system.

- Step 2: All bottle caps are automatically transferred to the automatic capping system.

- Step 3: The water is filled into the bottles at the water filling system and then automatically transferred to the automatic capping system.

- Step 4: The QC team will inspect the quality of the bottled water caps.

- Step 5: Apply the brand label to the bottle body. Then automatically pass through the shrink wrap machine.

- Step 6: Pack the bottled water into crates and transfer them to the transit warehouse. Perform storage procedures at the warehouse, completing the entire process.

Indeed, the process of producing purified bottled water that is clean and safe cannot be implemented without advanced technology and machinery. The bottled water filtration system is equipped with specialized equipment, modern production lines, and is fully enclosed. For any inquiries about equipment or products, please contact the hotline at 0913 543 469 or visit the company's address for assistance.

Update: 05/07/2022

Share:

Related projects

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News