Content

Authentic EDI equipment - electronic deionization for water treatment

Update: 26/07/2022

Share:

What is EDI equipment?

EDI equipment is one of the advanced water filtration technologies for high mineral removal nowadays. It operates by using energy to facilitate the permeation process, helping to create super pure water ions. EDI equipment provides users with ultra-clean water suitable for both domestic and industrial purposes.

In simple terms, EDI equipment is a water treatment technology that combines clean filtration, ion exchange, ion membrane exchange with electrical separation techniques. During the treatment process, the EDI equipment is divided into 3 completely separate water levels: Clean water accounts for about 90% - 95%. Concentrated water is water that can be recycled and further treated in subsequent cycles, accounting for 5% - 10%; Waste water accounts for 1%.

Currently, EDI equipment is mainly used for treating ultrapure water. When combined with reverse osmosis (RO) technology, it forms a professional and efficient clean water treatment system. The quality of water after passing through the Edi mineral removal system has high resistivity, averaging 18 MOhm. Therefore, this water source meets the ultra-pure standard and can serve industries requiring absolutely clean water.

Technical Specifications

Currently, there are various types of EDI equipment available on the market, each with different characteristics and technical specifications. In the following table, we share the specifications of popular Edi devices on the market:

| Model | Operating Voltage | Current | Flow Rate | Concentrated Flow/Ion Concentration | Electric Flow |

| Unit | V | A | m3/h | m3/h | m3/h |

| CP500S | 20-80 | 0.5-5.5 | 0.4-0.7 | 0.06-0.10 | 0.06 |

| CP1000S | 20-100 | 0.5-5.5 | 0.9-1.2 | 0.13-0.18 | 0.06 |

| CP2000S | 50-120 | 0.5-5.5 | 1.0-2.0 | 0.15-0.30 | 0.06 |

| CP3600S | 50-180 | 0.5-5.5 | 2.0-3.5 | 0.24-0.41 | 0.06 |

| CP4500S | 80-240 | 0.5-5.5 | 3.0-4.5 | 0.35-0.54 | 0.06 |

| CP5800S | 100-250 | 0.5-5.5 | 4.2-5.8 | 0.50-0.82 | 0.06 |

Operating Principle of EDI Equipment

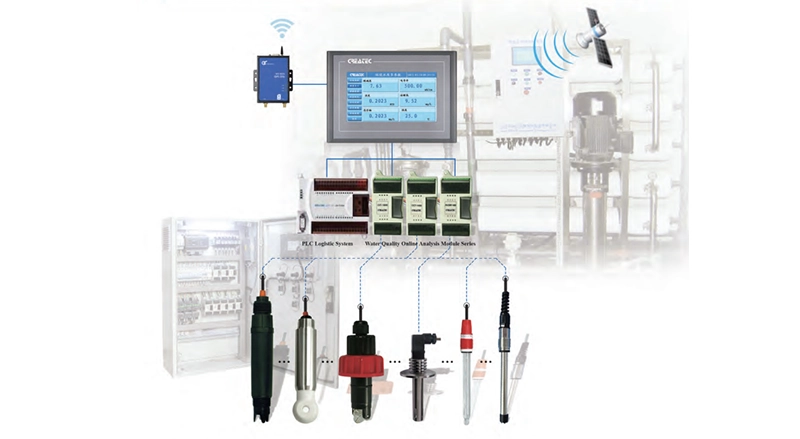

EDI technology consists of a power source, ion exchange membranes, and ion exchange resin beads. In this:

- Ion exchange membranes only allow ions of the same charge to permeate through.

- Ion exchange resin beads create dilute water compartments.

- Single exchange membranes create concentrated water compartments by ionic separation.

In general, the operating principle of EDI equipment is complex. However, to help customers understand the ion removal process of this equipment better, we briefly outline the operating principle as follows:

Ion Removal Process

The main purpose of this process is to remove cationic/anionic ions present in the water source.

Under the influence of an electric field, ion exchange resin beads between the membranes will form Hydroxyl and proceed to remove cations Ca++, Mg++, S, K+, NH+. After the ion exchange process, H+ and OH- ions are generated to replace the cation and anion ions in the water to create ultrapure water.

Ion Movement

After replacing all the necessary H+ and OH- ions, the ion exchange resin beads need to be regenerated. At that point, the EDI equipment will provide a 2-pole electric current, moving from the positive electrode to the negative electrode. Here, ions are removed from the water, with cations being attracted to the negative electrode. Conversely, anions are pushed towards the positive electrode.

When water is supplied to the system, positively charged anions will come into contact with the ion exchange resin beads and pass through the cation exchange membrane, being attracted to the negative electrode. Negatively charged anions, when in contact with the resin beads and exchange membrane, will be attracted to the positive electrode.

The cation membrane is located at the positive electrode, while the anion membrane is located at the negative electrode. The water in the concentrated compartments of the equipment is waste water containing the cations and anions that need to be removed.

Regeneration

EDI equipment does not require the use of chemicals for regeneration but uses electricity. Under the influence of an electric field, water molecules will dissociate into hydro and hydroxide ions, which help regenerate the cation and anion exchange resin beads.

Basic Features of EDI Equipment

Edi mineral removal water filtration system is one of the safest and most effective water treatment technologies today. This equipment combines many outstanding features such as:

- The machine can operate continuously and provide stable ultrapure water with minimal quality variation after deep filtration processes.

- No chemicals are required during the water filtration process, ensuring the safety of water quality.

- During the regeneration cycle after each water filtration, the machine does not need to be stopped. This allows for continuous supply of ultrapure water in large quantities without interruptions.

- The water production efficiency of EDI technology is very high, reaching up to 95%. This helps save water. Additionally, the waste water from the equipment can be reused for irrigation, household cleaning, etc.

- EDI equipment has a compact design, saving space for users.

- The operating and maintenance costs of EDI equipment are relatively low. Moreover, the equipment is safe to use, easy to install, and quick to set up, making it convenient and cost-effective.

In general, when comparing the initial investment and operating costs of EDI equipment with other water filtration technologies on the market, it is evident that this equipment requires much lower financial investment while still achieving the desired quality.

Applications of EDI Equipment

EDI equipment is used in water treatment across various industries, including:

- Application in providing ultrapure water for pharmaceutical, cosmetic production.

- Supplying clean water for the electricity industry, power generation, and optoelectronics industry.

- Using EDI equipment in the electronics industry for manufacturing smart, modern electronic devices such as ICs, PCBs, etc.

- Application in painting technology, surface polishing of household items, cars, or products requiring high-quality painting and polishing techniques.

- EDI equipment provides ultrapure water for laboratories, chemical research, and biological research.

- EDI equipment is also used to supply water for high-pressure steam boilers.

Where to Buy EDI Equipment?

Toan A Environmental Technology Joint Stock Company is one of the leading providers and technology transferors of EDI equipment on the market today. With a diverse range of models and superior product quality, Toan A confidently offers customers the best EDI equipment at affordable prices. Additionally, customers receive enthusiastic advice and support from experienced technical experts in the water treatment field.

Above is our sharing about EDI equipment. We hope that this information has helped you understand more about this equipment. If you have any further questions that need clarification, please do not hesitate to contact us at the hotline: 0913. 543. 469 for advice and answers from top experts in the water treatment industry.

Update: 26/07/2022

Share:

Related news

Industrial RO water filtration system: Optimal solution for clean water in production

Created at: 17/09/2024

Water purification is an essential process in many industries, especially in the pharmaceutical, electronics, and power generation sectors. One of the most effective methods for producing ultra-pure water is the DI-EDI water purification system. This syst

With the rapid development of modern industries today, pure water has played an extremely important role, not only as a crucial raw material for production but also as a decisive factor affecting product quality. Particularly in industries such as pharmaceuticals, electronics, energy, and food, the water source is required to be ultrapure. The DI (Deionization) water filtration system and EDI (Electrodeionization) have become the two leading technologies to meet this demand. Each system has its own advantages and limitations, suitable for specific industrial applications. Let’s explore the details of DI and EDI water filtration technologies with Toan A JSC in the article below!

Created at: 19/08/2024

Details of the structure, pricing of industrial RO water filtration system.

Clean water is not only an essential component but also a determining factor in the product quality of industrial enterprises operating in various industrial sectors today. Especially for industries such as food, pharmaceuticals, and electronics, ensuring clean water sources is a prerequisite for maintaining safety and hygiene standards. However, the issue of clean water in industrial production is currently facing many challenges, including increasing water pollution and pressure from unsustainable industrial development. Therefore, the application of advanced water filtration technologies, with the most common being industrial RO water filtration systems, has become the optimal solution chosen by many businesses to invest in. What are the capacities of these systems and how do they fit the production scale of businesses? Let's explore the details with TOÀN Á JSC in the following article!

Created at: 14/08/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News