Content

Xử lý nước sạch cấp cho các khu Công Nghiệp hiệu quả

Update: 05/07/2022

Share:

What is Industrial Water Treatment?

Industrial water treatment refers to the process of treating water through various treatment processes to provide clean, pure water. By constructing and using industrial water treatment systems, companies will find it easier to address the issue of clean water for workers and meet the demand for clean water in production.

It can be said that as the number of factories and industrial zones increases, the number of workers also increases. To facilitate work, most workers stay within industrial zones. Therefore, to serve daily activities, the water supply for workers always needs a large amount of water.

However, factories are often built far from city centers, in areas with less planning, making not only water supply but also transportation and other services more difficult. Building and installing industrial water filtration systems is crucial.

Benefits of Industrial Water Treatment

1. Supplying water for daily activities

Daily living activities cannot be without clean water. To ensure that workers have good health, it is necessary to provide them with clean water. Clean and pure water will provide people with good health, abundant energy, and a healthy living environment. This will help improve work efficiency.

2. Providing water for production activities

Not only daily human activities require clean water, but production activities also need clean water. Especially in industrial sectors such as food processing, metallurgy, pharmaceutical manufacturing, and cosmetics production. This will help the production process create safer and more efficient products.

Methods of Industrial Water Treatment

Depending on the water source and the water supply needs, industrial water treatment systems vary in scale.

To produce clean water, the system must combine multiple methods. To meet this requirement, Toan A's water treatment system combines physical, chemical, and mechanical methods. This results in clean, pure water, eliminating odors, impurities, and harmful substances.

1. Mechanical methods

This method includes facilities such as primary settling tanks, screens, sand settling tanks, and water filtration tanks. The main purpose is to remove inorganic and organic waste that cannot dissolve in water.

2. Chemical treatment of industrial water

This method includes processes such as aeration, preliminary chlorination, and coagulation. The main purpose of chemical water treatment methods is to create reactions to remove or transform harmful factors in water into a form that can be easily filtered out. This contributes to the cleanliness of the water.

3. Water treatment using chemical methods

Some common measures include using strong oxidizing agents, disinfection with chlorine, ozone, and ultraviolet rays. The main purpose is to remove all microorganisms, harmful substances, and remaining impurities from previous treatment processes.

Typically, to provide enough water for a cluster of companies in an industrial zone, the industrial water treatment system must have a very large capacity. This number can range from a few thousand to tens of thousands of cubic meters per day.

Equipment in Industrial Water Treatment Systems for Industrial Zones

The equipment not only ensures an adequate water supply for production activities but also helps protect the environment and the health of workers. This article will introduce the important equipment in industrial water treatment systems for industrial zones.

Filtration System

This equipment is responsible for removing impurities, bacteria, and small particles from the water source to ensure the quality of the output water. The main components include sand filters, activated carbon filters, and membrane filters.

Sand filters help remove large particles and debris, while activated carbon filters absorb organic substances, odors, and colors. Membrane filters, usually ultrafiltration or reverse osmosis (RO) membranes, in RO Industrial Water Filtration Systems can remove bacteria and tiny particles to an extremely small level.

Chemical Equipment

The chemical system plays a crucial role in treating and adjusting the water's chemical parameters. This equipment helps adjust pH, remove heavy metals, and other pollutants.

The equipment includes chemical storage tanks, dosing pumps, and mixing units. Chemical storage tanks are used to store necessary chemicals such as chlorine, acids, and alkalis. Dosing pumps deliver chemicals into the system accurately, while mixing units ensure that chemicals are evenly dispersed in water.

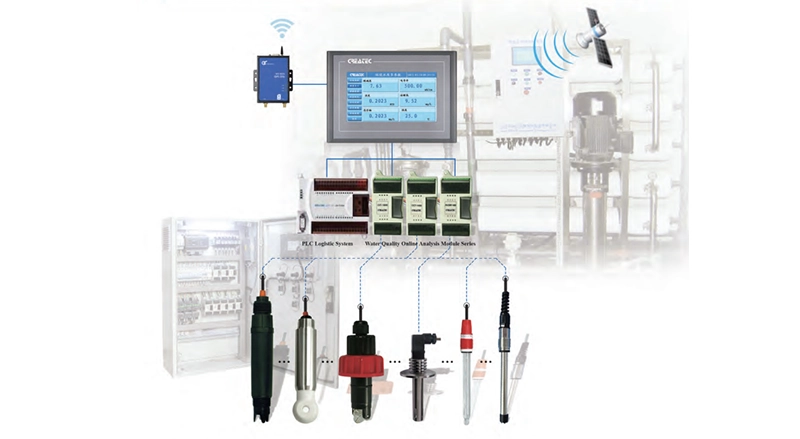

Control and Monitoring Equipment

To ensure efficiency and quality water standards, clean water treatment systems need to be equipped with intelligent control and monitoring devices. These devices include sensors, central control units, and SCADA systems (Supervisory Control and Data Acquisition).

Sensors monitor parameters such as turbidity, pH, temperature, and pollutant concentrations in water. The central control unit receives signals from sensors and adjusts the operation of other devices in the system. The SCADA system provides a user-friendly interface, helping manage and operate the industrial water treatment system efficiently.

Maintenance and Operation of the System

In addition to investing in modern equipment, maintaining and operating the industrial water treatment system is crucial. Regularly checking and maintaining filtration equipment, chemicals, and control systems ensure the system operates efficiently and durably. Training operators, raising awareness of the importance of clean water in production, is also crucial to maintaining water quality.

Technological Trends in Clean Water Treatment

With technological advancements, many new solutions in clean water treatment are being applied. Biological membrane filtration technology (MBR - Membrane Bioreactor), UV water treatment technology, and advanced automation systems are becoming trends. These technologies not only improve treatment efficiency but also optimize operation and maintenance costs.

Industrial water treatment systems for industrial zones include many important devices such as filtration systems, chemical systems, and control and monitoring devices. Each device plays an essential role in ensuring water quality meets standards, protecting the environment, and the health of workers.

To achieve the highest efficiency, businesses need to invest appropriately and closely manage their industrial water treatment systems. Monitoring and applying new technologies will also help improve efficiency and sustainability for clean water treatment systems in the future.

Update: 05/07/2022

Share:

Related news

Water treatment systems for boilers: Structure and operation process

The water treatment system for steam boilers is an important investment to ensure the efficient, safe, and durable operation of the boiler. By selecting and operating the appropriate water treatment equipment, businesses can save costs, increase productivity, and protect the environment.

Created at: 06/07/2024

Industrial Nano Water Filtration System - Efficient & Cost-effective

The Industrial Nano Water Filtration System is the optimal solution for removing impurities, bacteria, and harmful substances, ensuring the quality of the water input for the production process.

Created at: 05/07/2024

Water filtration systems for household use, treating domestic water.

Household iron removal water filtration systems are designed to remove iron and other impurities, aiming to improve the water quality for domestic use.

Created at: 04/07/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News