Content

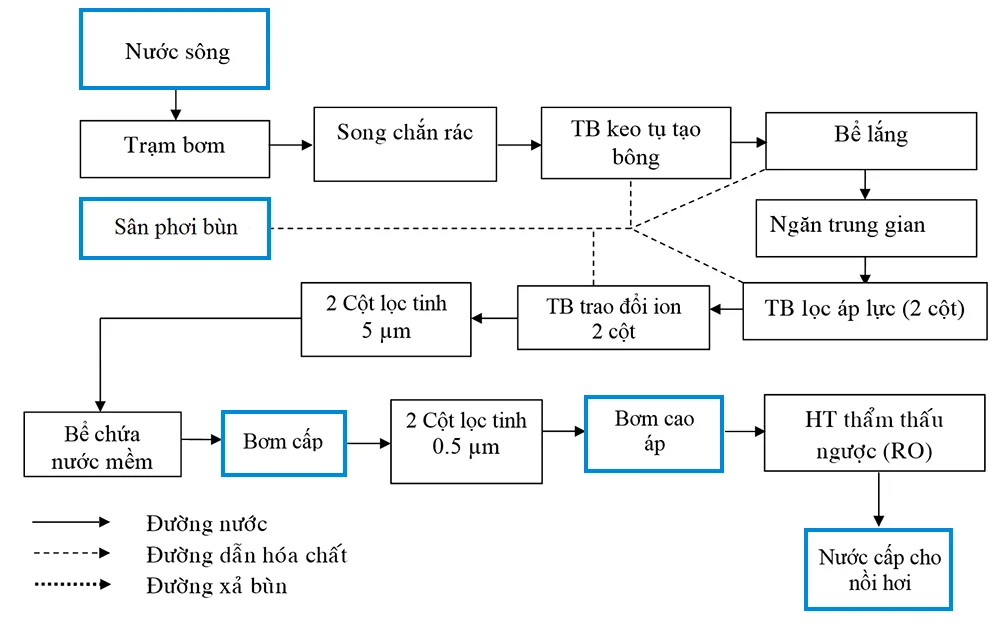

Water treatment systems for boilers: Structure and operation process

Update: 06/07/2024

Share:

What are the benefits of treating boiler feed water?

Treating boiler feed water is an essential step in the operation of a boiler. Boiler feed water is usually taken from tap water in industrial areas or from water sources such as rivers, lakes, or well water.

These water sources are often called hard water because they contain impurities such as sediment, metal ions (calcium, magnesium...), and other organic substances. If these impurities are not removed, when introduced into the boiler, they can cause serious problems such as:

1. Scale removal

Impurities in the feed water, when exposed to the high temperature of the boiler, will precipitate and adhere to the pipe walls and heat exchange surfaces, causing scale formation. Over time, thick scale buildup can lead to pipe blockages, reduce heat exchange efficiency, increase fuel consumption, and may even damage the boiler feed water treatment system, or worse, pose a risk of boiler explosion.

2. Corrosion prevention

Untreated water may contain ions that cause corrosion, such as chlorides, sulfates. Corrosion not only reduces the lifespan of the boiler but also poses a risk of leaks, compromising safety during operation.

3. Foam and water carryover treatment

Organic impurities in untreated feed water can cause foaming, leading to water carryover and affecting the quality of the steam produced.

All of the serious issues mentioned above due to inadequate feed water treatment will reduce the operational efficiency of the boiler, increase the risk of equipment failure, and threaten labor safety, resulting in economic losses for the business. To prevent these risks, businesses need to equip a boiler feed water treatment system, bring the feed water to standard levels, and ensure the safe operation of the boiler.

What does a boiler feed water treatment system consist of?

The equipment that makes up a boiler feed water treatment system will depend on the quality of the feed water and the capacity of the boiler, but fundamentally, it will include the following main components:

1. Filtration pump

Filtration pumps are usually made of stainless steel or aluminum alloy, ensuring high durability and good corrosion resistance. The construction of a filtration pump includes an electric motor, pump shaft, impeller, and pump chamber.

The filtration pump functions to push water through filtration and treatment systems, ensuring clean water supply and sufficient pressure for the boiler. The filtration pump also helps circulate water in the system, minimizing the risk of dirt buildup and increasing the operational efficiency of the boiler.

2. Filter column

Filter columns can be made of composite or stainless steel. Composite is a synthetic material, lightweight, durable, and highly corrosion-resistant. Stainless steel, or stainless steel, has good mechanical strength, can withstand high pressure, and is not corroded in water environments. The column body contains layers of filter materials, including activated carbon, quartz sand, and other filter media, to remove impurities, dirt, and bacteria in the water.

The filter column functions to remove impurities, dirt, and bacteria in the water, improving the quality of the feed water for the boiler. The filter column also helps reduce the hardness of the water, prevent scale formation in the boiler, increase the lifespan and efficiency of the boiler.

3. Filter valve

Filter valves can be made of plastic or metal, depending on the system requirements. There are two types of filter valves: Automatic valves controlled by electricity or compressed air, or manual hand valves that require manual operation.

The filter valve controls the water flow through the filtration system, ensuring uniform and efficient filtration. Automatic valves can automatically adjust water flow, minimize operator intervention, and increase the accuracy of the filtration process. Hand valves allow adjusting water flow according to actual needs, flexible in operation.

4. Salt regeneration tank

The salt solution tank is usually made of plastic or composite, with high corrosion resistance and durability.

The salt solution tank provides regeneration solution for ion exchange resin beads, helping maintain the effectiveness of the water softening process. This regeneration process helps the resin beads restore their ion exchange capacity, remove hardness ions in water such as calcium and magnesium, improve the quality of the feed water for the boiler.

5. Filter media for softening system

Ion exchange resin beads are made of polystyrene resin, with a porous structure and a large surface area, allowing for efficient ion exchange. The resin beads have the ability to absorb hardness ions in water such as calcium and magnesium, and replace them with sodium or potassium ions.

Ion exchange resin beads function to soften water by removing hardness ions, such as calcium and magnesium, reducing the hardness of the feed water for the boiler. This process not only improves water quality but also prevents scale formation in the boiler, increasing the lifespan and efficiency of the boiler.

In addition to the components mentioned above, depending on the feed water source and water quality treatment requirements, businesses may equip additional components such as: trash screens, settling tanks, sludge drying beds... to preliminarily separate pollutants, debris in water before entering the intermediate storage tank to serve the main treatment stage of the system.

What is Toan A's boiler feed water treatment system installation process?

With over 20 years of experience in water treatment, Toan A JSC is the leading provider of installation services with a strict and optimized boiler feed water treatment process, ensuring maximum customer satisfaction, including the following steps:

Survey and evaluation

Toan A's experts will conduct a detailed survey and evaluation of the incoming water source for the business's boiler, identify impurities and pollution levels to provide the most appropriate treatment solution.

System design

The boiler feed water treatment system is designed based on the specific characteristics of each customer, ensuring optimal efficiency and cost savings.

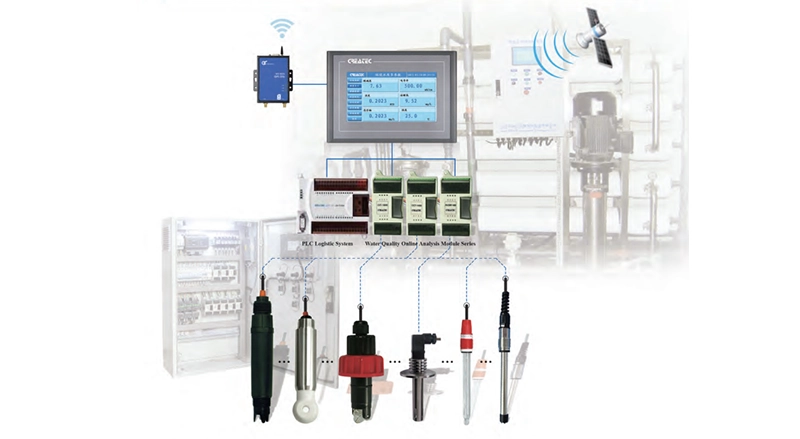

Use of advanced technology

Toan A applies the latest technologies and equipment in the water treatment process, such as mechanical filtration, chemical treatment, and combined methods to completely remove impurities and protect the boiler from corrosion.

Professional installation and operation

The boiler feed water treatment process is installed and operated by Toan A's team of professional engineers and technical staff, ensuring stable and efficient system operation.

Maintenance and technical support

Toan A provides regular maintenance and technical support services to ensure the system is always in the best condition, minimizing risks and enhancing efficiency.

Contact Toan A via hotline 0913.543.469 today for free consultation from experts on optimal boiler feed water treatment system for your business!

With a team of experienced experts and advanced technology, Toan A is committed to providing you with an effective, reliable, and tailored boiler feed water treatment solution for your business. Let us help you protect your boiler, optimize performance, save costs, and contribute to the sustainable development of your business.

Update: 06/07/2024

Share:

Related news

Water treatment systems for boilers: Structure and operation process

The water treatment system for steam boilers is an important investment to ensure the efficient, safe, and durable operation of the boiler. By selecting and operating the appropriate water treatment equipment, businesses can save costs, increase productivity, and protect the environment.

Created at: 06/07/2024

Industrial Nano Water Filtration System - Efficient & Cost-effective

The Industrial Nano Water Filtration System is the optimal solution for removing impurities, bacteria, and harmful substances, ensuring the quality of the water input for the production process.

Created at: 05/07/2024

Water filtration systems for household use, treating domestic water.

Household iron removal water filtration systems are designed to remove iron and other impurities, aiming to improve the water quality for domestic use.

Created at: 04/07/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News