Content

Industrial Wastewater Treatment System: Comprehensive Solution

Update: 13/08/2024

Share:

I. Common Industrial Wastewater Treatment Methods Today

With the development of many industries today, wastewater treatment requires diverse technologies to suit the quality and different types of wastewater. Some common industrial wastewater treatment technologies today include:

1. Chemical Method

This method applies by using chemicals to create chemical reactions to remove or convert pollutants in wastewater into less harmful forms. This method includes measures such as coagulation, precipitation, neutralization, and oxidation-reduction.

The advantage of this method is that it is highly effective in removing heavy metals, organic compounds, and dissolved pollutants and can be customized to treat specific types of wastewater. However, the cost of chemicals and operation is relatively high, and companies applying this method also need to manage the waste generated from the treatment process such as sludge and exhaust gases.

Wastewater treatment using the chemical method is commonly applied in industries such as chemical production, electroplating, textile dyeing, and the food industry.

2. Biological Method

This method uses microorganisms to decompose organic compounds in wastewater. This method is divided into two types: anaerobic (without oxygen) and aerobic (with oxygen).

Industrial wastewater treatment using the biological method is highly effective in removing organic compounds and nutrients (such as nitrogen, phosphorus), saving energy, and being environmentally friendly. However, this method also has the disadvantage that the treatment process is often prolonged and depends on environmental conditions such as temperature, pH, and if this method is applied, companies also need to control the process well to avoid system failures.

This method is widely applied in industries such as food, beverage, paper production, and domestic wastewater treatment.

3. Mechanical Method

Wastewater treatment using the mechanical method involves using devices such as screens, settling tanks, and filters to remove suspended solids and large-sized impurities. This is often the first step in the wastewater treatment process to reduce the load of pollution before the wastewater is further treated by other methods.

The advantage of this method is that it is simple, easy to implement, and cost-effective, with high efficiency in removing large solid particles and impurities. However, this method cannot treat dissolved pollutants or organic compounds. To treat these substances, companies need to combine with other methods. Therefore, industrial wastewater treatment using the mechanical method is often applied in industries with a large amount of solid impurities such as textile, paper production, and food processing.

4. Membrane Filtration Method

Membrane filtration method uses membranes such as RO, UF, MF to remove solid particles, bacteria, viruses, and dissolved substances from wastewater. The advantage of this method is that it can be combined with other methods to treat complex wastewater, effectively removing pollutants with small sizes without using chemicals and especially can reuse water after filtration.

However, this method also has the disadvantage of requiring high investment and operation costs, and also requires regular maintenance to maintain the effectiveness of the membranes.

Wastewater treatment using the membrane filtration method is suitable for industries that require high-quality reused water such as electronics manufacturing, pharmaceuticals, and food production.

II. Advanced Industrial Wastewater Treatment System Process from Toan A JSC

With 21 years of experience in the water treatment industry and having implemented and installed wastewater treatment systems for thousands of projects, large and small, in various fields and industries nationwide, and based on the advantages and disadvantages of each method, TOAN A JSC has developed an industrial wastewater treatment process with advanced technologies, providing high efficiency, widely applied in many fields today.

Details of the industrial wastewater treatment system process include:

1. Trash Rack Screen

This is the first step in the system, installed at the wastewater inlet to remove large objects from the wastewater to protect equipment and downstream treatment processes from damage and clogging, helping to maintain system efficiency. Trash rack screens are usually grids or screens with openings to filter out large objects such as debris, branches, packaging, and fabric scraps.

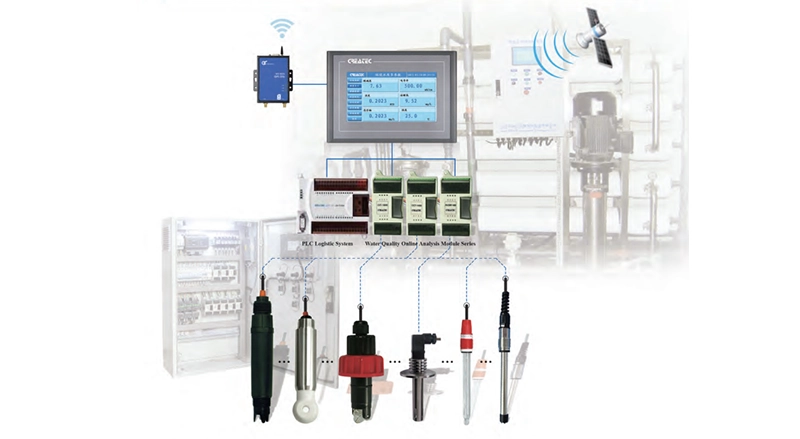

Devices to measure the pH concentration, SS in wastewater are also installed in this area to capture the characteristics of the water source and have the most effective treatment method.

2. Pumping Well (Pumping Chamber)

The pumping well is built in a submersible model to collect wastewater from the factory and pump the wastewater to the downstream system through pumps installed in the well. A flow meter for the inlet wastewater is also installed in the pumping well. This well can also settle and remove solids in the wastewater.

3. Fine Trash Rack Screen

With much smaller filter openings compared to the coarse trash rack screen, the fine trash rack screen helps remove debris with sizes from 0.75mm and above, then the wastewater goes to the downstream components, reducing pressure load for the subsequent treatment system.

4. Grease and Oil Separator Tank

Due to the lighter specific gravity of grease and oil than water, they will float on the surface of the wastewater. A scraper system in the tank will scrape and collect grease and oil to the oil storage tank and send it to specialized processing companies. The remaining wastewater will continue to the next part of the system, the equalization tank.

5. Equalization Tank

Where wastewater is mixed evenly through a mixing system to stabilize flow rate and pollutant concentration, avoiding sudden fluctuations, helping the subsequent treatment processes operate more effectively and stabilizing the pH concentration in wastewater.

6. Aerotank

One of the crucial components in industrial wastewater treatment systems, especially in aerobic biological treatment processes.

The tank is usually rectangular or circular, with an air diffusion system or an air distribution system to provide oxygen to microorganisms.

The main function of the Aerotank is to decompose dissolved organic compounds in wastewater through the activity of aerobic microorganisms. This process helps reduce BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) of wastewater. The Aerotank also helps transform nutrients such as nitrogen and phosphorus through nitrification and phosphorus removal processes, preventing eutrophication in natural water sources.

7. Biological Settling Tank

Where dead microbial cells and activated sludge settle after biological treatment, making the treated wastewater cleaner. The settled sludge at the bottom will be transferred to a sludge storage tank for treatment. Some will be recycled back to the Aerotank to ensure stable flow and concentration for microbial activity. The water part will be transferred to the intermediate tank.

8. Intermediate Tank and Disinfection

The intermediate tank's main function is to stabilize the flow rate and wastewater concentration before transferring to the disinfection tank.

In the disinfection tank, wastewater will be disinfected using disinfectants such as chlorine, ozone, or UV rays to kill bacteria, viruses, and disease-causing microorganisms in wastewater, ensuring the safety of the wastewater before discharging into the environment.

9. Sludge and Sediment Treatment System

The sludge treatment system includes processes such as compression, digestion, and sludge drying to reduce the volume and moisture content of sludge waste, turning it into easy-to-handle or reusable forms.

Industrial wastewater treatment systems play a crucial role in protecting the environment and ensuring compliance with strict regulations on wastewater discharge. With treatment stages from mechanical, chemical to biological, each system must be designed and operated to suit the characteristics of wastewater from each industry. To ensure the effectiveness and durability of the system, choosing a reliable supplier for materials and design and construction is a prerequisite. Toan A Technology and Environment Joint Stock Company, with 21 years of experience and reputation in the market, is proud to be a reliable partner in providing comprehensive wastewater treatment solutions, from design to construction and supply of high-quality materials. For more details about our services and solutions, please contact:

- Zalo: 0913.543.469

- Projects: 0913.543.469

- Hotline North: 0822.211.666

- Hotline South: 0822.212.666

- Messenger: https://www.facebook.com/toanajsc

Update: 13/08/2024

Share:

Related news

Effective Pharmaceutical Wastewater Treatment Solutions from Toan A JSC

Created at: 04/09/2024

Optimal Solution for Medical Wastewater Treatment from Toan A JSC

Created at: 04/09/2024

Advanced domestic wastewater treatment technology by Toan A JSC

Domestic wastewater is one of the largest sources of pollution to the environment if not treated properly. In Vietnam, besides individual households, urban areas, apartment buildings, restaurants, hotels, and service establishments are required to comply with the treatment of domestic wastewater according to the QCVN 14:2008 standard set by the Ministry of Natural Resources and Environment to ensure environmental safety and human health. Currently, there are many methods for treating domestic wastewater, each with its own characteristics and specific applications, suitable for different types of wastewater and specific requirements. Let's explore this issue further with Toan A JSC in the following article!

Created at: 14/08/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News