Content

Xử lý nước thải dược phẩm: Công nghệ và Quy trình thực hiện

Update: 05/07/2022

Share:

Origin of Pharmaceutical Wastewater

Pharmaceutical wastewater is water discharged from the production of drugs, capsule shells, tablets, equipment cleaning... This type of water contains high levels of oil and grease, suspended solids harmful to pumps, water pipes, and microbial activities. Moreover, if not treated properly, it can pose risks to the surrounding environment.

Wastewater from the process of cleaning equipment, materials, and tools used in pharmaceutical production. This wastewater contains hard-to-treat compounds such as β-lactam compounds, reagents, solvents,... These compounds, if not properly treated and discharged directly into the environment, can kill aquatic organisms, affecting the daily lives of people around,...

It can be seen that pharmaceutical wastewater contains many toxic substances and various chemical components. Therefore, treating pharmaceutical wastewater correctly is important to protect the natural environment and human living conditions.

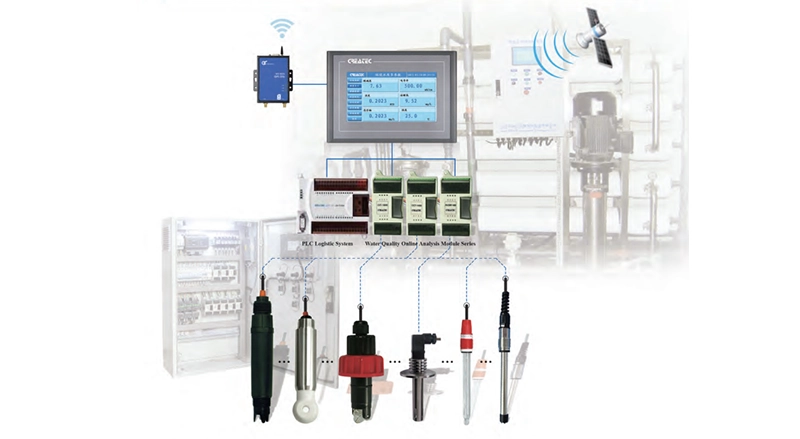

Pharmaceutical Wastewater Treatment Technologies

If pharmaceutical wastewater is not treated properly, it can be a source of environmental pollution and disease transmission. Because wastewater contains various chemicals, oils, and substances that are difficult to degrade. To thoroughly treat hazardous substances and pollutants in wastewater, a combination of chemical and biological methods is needed.

Membrane Filtration Method

This is the most commonly used technology. This method uses a membrane filter with small pore sizes to filter wastewater. Pollutants and contaminants will be trapped in the membrane filter.

There are many different types of membrane filters available today, typically using filters with very small pore sizes, membrane fibers on the side, capable of withstanding water pressure.

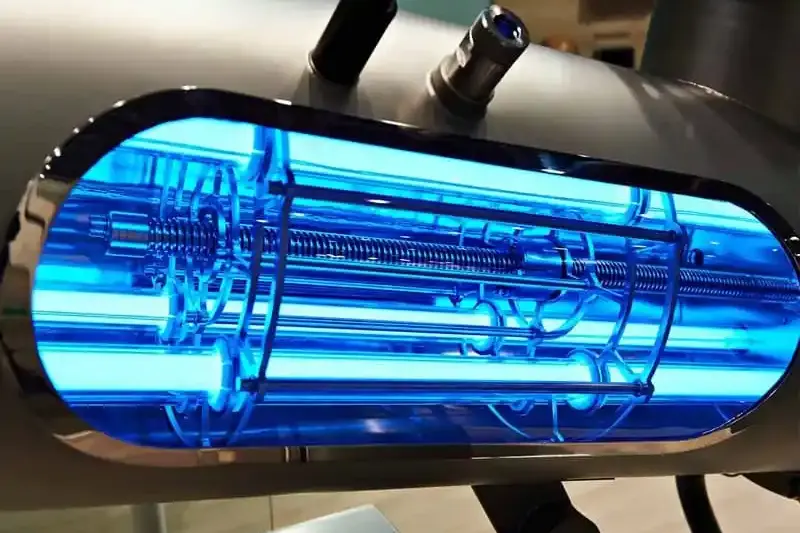

UV Irradiation

This is considered one of the most common methods today. UV lamps, gamma rays can be used to eliminate organic and inorganic substances in wastewater. Using ion irradiation techniques can remove almost 100% of hazardous impurities and pollutants from water.

Using Nano Particles

This technology can remove objects smaller than 100 nanometers. However, this technology is usually only used in small-scale projects due to its high cost and is not as widely used as the two technologies above.

Biological Decomposition Technology

This method uses a mixture of microorganisms to treat pharmaceutical wastewater to remove compounds, organisms that cause pollution. The microbial mixture consists of enzymes and safe microorganisms capable of purifying water. Biological decomposition technology brings many benefits. It not only removes pollutants but also increases the purity of water.

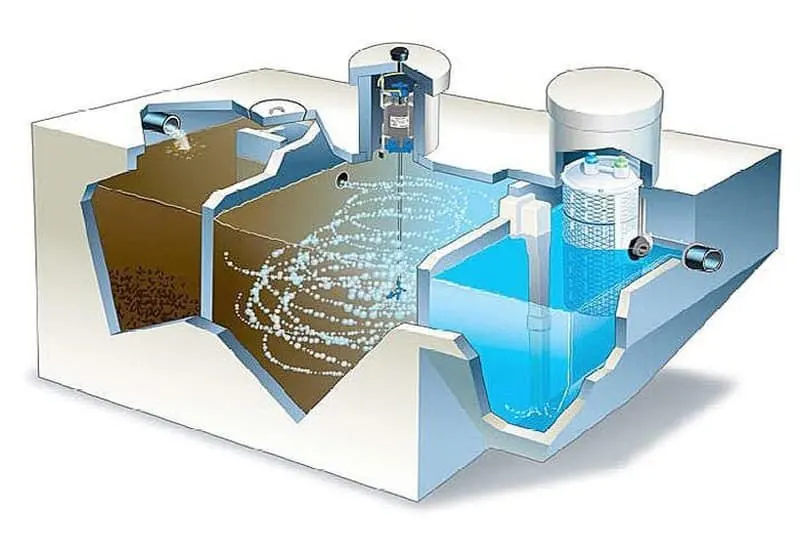

Biological Reactor Tank

The reactor tank is a method that uses tanks containing bacteria such as methane-producing bacteria, aerobic bacteria,... to treat pharmaceutical wastewater.

Pharmaceutical Wastewater Treatment Process

To treat pharmaceutical wastewater, a pharmaceutical company needs to apply a technological process with all the necessary steps to eliminate harmful impurities in water.

Trash Screen

The incoming wastewater is passed through trash screens to remove solid waste, impurities. This prevents pump clogging and reduces the efficiency of filtration tanks. The removed waste will be moved to a waste storage area.

.webp)

Through filtration tanks, toxic substances, oils, and greases will be gradually removed. The functions and mechanisms of operation of the tanks are as follows:

Oil-Grease Separator Tank

The oil separation tank is responsible for removing oil and grease, ensuring water does not contain oil in the next filtration process.

The separated oil will be transferred to an oil storage tank.

Conditioning Tank

The conditioning tank stabilizes the wastewater for the next treatment processes. When calculating the capacity and volume of the conditioning tank, it depends on the retention time, as well as the tank's waterproofing ability.

.webp)

The conditioning tank stabilizes the concentration and flow rate of wastewater. It provides stability to the water flow for smoother subsequent processes. This equipment helps evenly mix the water flow. It also eliminates gas decay conditions. Then, the water is moved to the flocculation tank.

Flocculation-Flotation Tank

The flocculation-flotation tank is designed as a single tank divided into two compartments, saving space. Using the flocculation method to remove COD and color-forming substances. A high-speed mixing system in the flocculation compartment will blend flocculation chemicals such as PAC, Iron Phenol, Aluminum Phenol. After this process, the wastewater will be moved to the flotation compartment.

In the flotation tank, a mixing system is installed. When constructing the flocculation-flotation tank, the speed and size of the stirrer blades need to be calculated. This will help create large flocs without breaking them. Flocculation chemicals will help the flocs stick together to form large, dense flocs that settle slowly.

Sedimentation Tank I

Sludge and wastewater will be separated in Sedimentation Tank I. The sludge flocs will settle down due to the density difference with wastewater. The upper water portion will be returned to the oxidation tank. The sludge portion will be sent to the sludge compression tank periodically.

Oxidation Tank

The oxidation tank helps remove poorly soluble compounds in water such as β-lactam compounds, gelatin ring compounds. Ozone gas will be supplied in the oxidation tank. Ozone is a strong oxidizing agent that helps destroy many poorly soluble organic compounds. Especially, ozone can decolorize, remove ring compounds like phenol, increase DO,...

UASB Reactor

UASB is a biological treatment technology for methane-producing bacteria, helping treat wastewater with high BOD and COD levels. The UASB reactor is designed for water distribution from bottom to top and maintains a suitable water flow.

The tank is designed with a water distribution system at the bottom of the tank, treatment layers, and phase separation system. The removal of organic impurities occurs in the methane-producing sludge layer.

In addition, the phase separation system helps separate solid-liquid-gas phases. Evaporated gas will be collected. The sludge will settle to the bottom of the tank. The remaining water will be directed to the aerobic biological tank.

Aerobic Biological Tank

In the aerobic wastewater treatment tank, wastewater is in contact with microbial sludge and continuously aerated. Aeration ensures continuous oxygen supply for microbial activity and maintains active sludge in a suspended state. The intensity and amount of air supplied to the system need to be accurately calculated to prevent breaking the sludge flocs.

Sedimentation Tank II

In Sedimentation Tank II, active sludge will settle down. Gravity and the density difference between active sludge and wastewater help maintain tank operation. A portion of the sludge will be recirculated to the Aerotank to nourish microorganisms. The remaining portion will flow to the disinfection tank through serrated channels.

Disinfection Tank

The tank is designed with partitions to optimize the diffusion of disinfectants into the water flow. Because pharmaceutical wastewater contains many bacteria, pathogens causing diseases,... disinfectants will eliminate all these microorganisms.

Pressure Filtration Tank

All suspended solids, small-sized organic matter will be removed in the pressure filtration tank. The tank uses filtering materials such as sand filters, stone water filters, activated carbon... To determine the amount of activated carbon, sand, stone used in the filter tank, you need to know the diameter and height of the filter column.

Sludge Holding Tank

The amount of sludge generated from the treatment process will be collected in the sludge holding tank. The tank is used not only to store sludge but also to separate water from sludge. This water portion will be returned to the conditioning tank. The remaining sludge will be collected and treated periodically according to regulations.

Where to Choose Pharmaceutical Wastewater Treatment Services?

If wastewater is not treated properly, it can still have serious consequences. Therefore, choosing a reputable, quality wastewater treatment system construction company is essential.

Toan A is a unit with over 20 years of experience in the water treatment field. With a team of experts with many years of experience in the industry and modern equipment systems, the company will optimize the system. Providing you with the best pharmaceutical wastewater treatment system.

Hope this article has provided you with useful information. If you need to build a pharmaceutical wastewater treatment system, you can contact the hotline number 0913.543.469 of Toan A for advice from our top experts.

Update: 05/07/2022

Share:

Related news

Industrial wastewater refers to the contaminated water generated from industrial activities. It typically contains a variety of pollutants, such as chemicals, heavy metals, oils, and other harmful substances. The composition of industrial wastewater can v

Industrial wastewater is contaminated water that can harm human health and the environment if not properly treated. The article below will provide more information about this hazardous wastewater and how to treat it most effectively.

Created at: 05/07/2024

NIKAWA - Bringing pure water to every family

Nikawa has become a familiar name to Vietnamese consumers, offering a range of home and industrial water filtration systems. These products utilize advanced technology to completely remove impurities, bacteria, viruses, and heavy metals from water, providing users with pure and safe water.

Created at: 27/05/2024

VICAN: A reputable supplier of water filtration and wastewater treatment solutions.

Vican is a reputable brand under the Vican International Group, specializing in providing advanced water filtration and wastewater treatment solutions for various applications, ranging from households and businesses to industrial zones or large-scale projects. With over 20 years of extensive experience in the industry, Vican has established a leading position in the Vietnamese market and expanded internationally, offering optimal solutions to customers worldwide.

Created at: 27/05/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News