Content

Bể lắng đứng trong xử lý nước cấp và cách tính toán

Update: 05/07/2022

Share:

What is a vertical settling tank?

A vertical settling tank is a type of tank made of stainless steel (inox) and coated with paint on the outside. They are usually designed in two main shapes: cylindrical or square with a conical bottom.

This type of tank is used for mechanical water treatment, with the task of separating solid particles. These solid particles will settle down at the bottom of the tank and be pumped out.

This vertical settling tank is also known as a centrifugal settling tank, designed similarly to a settling tank. In the mixed water and sludge tank, the water along with the sludge will be transported from bottom to top.

During this process, the sludge and heavy solid particles will settle down at the bottom of the tank. Meanwhile, the clear water without solid particles will be directed through a sawtooth channel to exit for further treatment.

Currently, this type of tank is present in most industrial water treatment systems at factories, constructions, enterprises, industrial zones, or used in households.

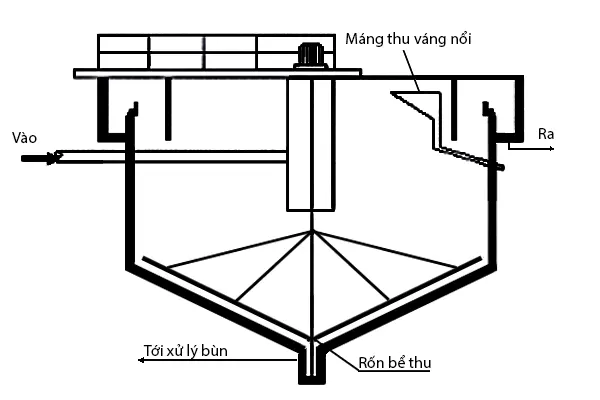

Structure of a vertical settling tank

The tank is usually made of Carbon Steel CT3 material combined with anti-corrosion paint for good durability. Additionally, there are devices built of bricks or concrete, often with small volumes.

The tank has dimensions with diameters ranging from 4 to 9 meters depending on the system's scale. Water in the tanks is pumped from the bottom upwards in a vertical direction.

The structure of a vertical settling tank consists of 2 shells with 4 main parts:

- The outer shell of the tank includes the bottom rake assembly to collect sludge.

- The central pipe section serves to direct the water flow from bottom to top.

- The sawtooth channel is where water is collected after solid particles have settled, combined with the task of blocking floating foam.

- The sludge collection part is equipped with a sludge scraper blade in the system.

The vertical settling tank has the task of storing water for a certain period. During this time, suspended solids under the influence of gravity created by the tank's structure and operating principle will settle deeply to the bottom.

Working Principle

To understand the settling process and how sludge settles effectively, you need to understand the working principle of the tank. Toàn Á will provide you with information about the working principle of the tank below.

Phase 1

The vertical settling tank operates on the principle of reverse flow. Water is introduced through a flow channel into the central pipe section and exits.

At that point, the water will collide with the tank wall and carry the water upwards from the bottom. Subsequently, the clarified wastewater will continue to pass through the sawtooth channel for the next treatment process.

Phase 2

As the water flows out through the pipe and rises, the water has a stable velocity ranging from 0.2 - 0.5 m/s. At this point, inert particles, sludge, will be affected by gravity to settle down in the conical sludge collection area. The sludge will be discharged by a static pressure pump through a pipeline designed to be lower than 1.5m compared to the water level in the tank.

Vertical settling tanks have the ability to remove non-dissolved solid particles, sludge in water. The tank's working efficiency reaches 50% - 70% for suspended solids and 25% - 40% for organic matter. Although the sludge filtration capacity of the tank is not high, with a simple design, low management costs, and saving construction space, vertical settling tanks are still widely used today.

Summarizing information about vertical settling tanks in water treatment will help you understand more about this equipment. From there, you can consider installing it for your factory's water treatment system, production unit.

Applications of a vertical settling tank

Currently, various types of vertical settling tanks are applied in many domestic or industrial wastewater treatment methods with many advantages:

-

Excluding solid particles, organic sludge, or biological sludge.

-

Performing sand settling work.

-

Treating sludge in wastewater by compressing sludge.

-

Removing microorganism sludge in wastewater.

For industrial wastewater treatment systems: they play a role in separating sludge when various chemicals react to form solid particles, used as sand settling tanks or primary settling tanks. Additionally, the tank can also be used in the process after an Aerotank biological aerated tank with the task of separating sludge, collecting various solid particles.

Calculating a vertical settling tank - Phase 1

The calculation of a vertical settling tank is as follows:

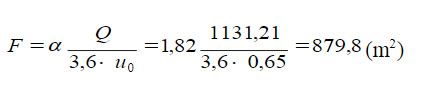

Settling Area

- Q = 27,149 (m3/day, night) = 1131.21 (m3/h) = 0.31 (m3/s), settling efficiency R = 50%.

- The remaining SS content after passing through the first settling tank is: 180×50% = 90 (mg/l).

- U0 = 0.65 mm/s (Regulation from 0.83 - 2.5 m/h or 0.22 - 0.7 mm/s).

- The coefficient considering the influence of turbulent flow: α = 1.82.

- Suspended solids concentration SS = 180 mg/l, color intensity M = 25 Pt - Co.

Settling Area

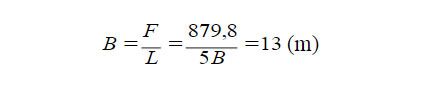

Width of the Settling Area

Length of the Tank

L = 5B = 65 (m)

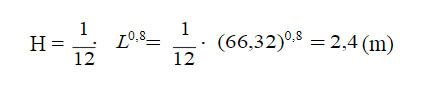

Height of the Settling Area

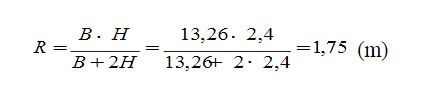

Hydraulic Radius

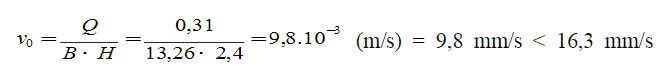

Flow Velocity in the Tank

Above is the information we want to share about vertical settling tanks and the calculation method for water treatment. If you want to learn more about this product, you can contact the experts at Toàn Á JSC. We are ready to support and help solve any issues.

Update: 05/07/2022

Share:

Related news

Industrial wastewater refers to the contaminated water generated from industrial activities. It typically contains a variety of pollutants, such as chemicals, heavy metals, oils, and other harmful substances. The composition of industrial wastewater can v

Industrial wastewater is contaminated water that can harm human health and the environment if not properly treated. The article below will provide more information about this hazardous wastewater and how to treat it most effectively.

Created at: 05/07/2024

NIKAWA - Bringing pure water to every family

Nikawa has become a familiar name to Vietnamese consumers, offering a range of home and industrial water filtration systems. These products utilize advanced technology to completely remove impurities, bacteria, viruses, and heavy metals from water, providing users with pure and safe water.

Created at: 27/05/2024

VICAN: A reputable supplier of water filtration and wastewater treatment solutions.

Vican is a reputable brand under the Vican International Group, specializing in providing advanced water filtration and wastewater treatment solutions for various applications, ranging from households and businesses to industrial zones or large-scale projects. With over 20 years of extensive experience in the industry, Vican has established a leading position in the Vietnamese market and expanded internationally, offering optimal solutions to customers worldwide.

Created at: 27/05/2024

Water Filter Columns

Water Filter Columns

Water Filtration Membranes

Water Filtration Membranes

Control Valves

Control Valves

Water Filter Cartridges

Water Filter Cartridges

Water Pumps

Water Pumps

Water Filtration Equipment

Water Filtration Equipment

Water Filtration Components

Water Filtration Components

Water Filtration Materials

Water Filtration Materials

Heat Pump Water Heaters

Heat Pump Water Heaters

Products

Products  Solutions

Solutions  Project

Project  News

News